Part 1: Introduction Container style plant factory

Container style plant factory is an innovative agricultural production model, and scientific planting breaks the constraints of spring, summer, autumn, and winter seasons on plant growth. It is a sustainable and efficient planting method. This mode is suitable for year-round periodic limited yield planting in extreme weather and harsh conditions such as plateaus, islands, cold regions, remote areas, and uninhabited areas. By using intelligent devices to accurately control the temperature, humidity, light, carbon dioxide, and nutrient solution required for plant growth, the yield and quality of plants can be improved, achieving efficient production throughout the year and reducing production costs& Nbsp;

The containerized plant factory adopts modular design from a design perspective, which is more flexible and efficient in construction and expansion, helping to reduce resource waste and environmental impact; The plant factory adopts energy-saving technology, reduces energy consumption, can be recycled, has a long service life, and can reduce the generation of a large amount of waste, thereby reducing the impact on the environment; Container style plant factories achieve efficient water and fertilizer management and resource recycling by precisely controlling environmental conditions such as temperature, light, humidity, etc. This management approach can not only improve the yield and quality of agricultural products, but also reduce the waste of resources such as water and fertilizer. At the same time, plant factories reduce pollution to the external environment through closed production methods& Nbsp;

This sustainability not only helps to reduce resource waste and environmental impact, but also improves agricultural production efficiency and quality, providing new directions for future agricultural development.

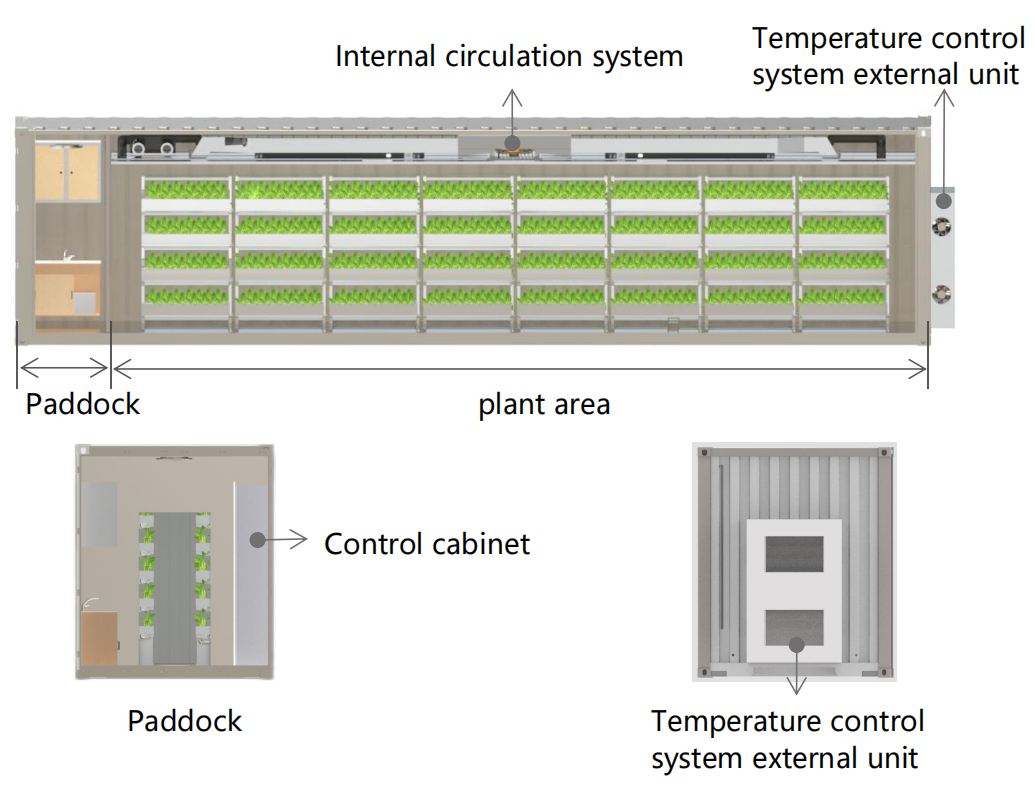

Figure 2.1 Matrix version containerized plant factory

Hydroponic containerized plant factory:

Figure 2.2 Hydroponic containerized plant factory

Part 2: Structure of a containerized plant factory External structure of containerized plant factory

2.1 Selection of External Structure Materials;

The external structure of the containerized plant factory adopts SPA-H weather resistant steel. In containerized plant factories, the external structure often needs to withstand natural environmental tests such as wind, rain, and temperature changes. Therefore, using SPA-H weather resistant steel can ensure the stability and durability of the structure. It has high strength and toughness, and can withstand large loads and impacts; Good corrosion resistance, with a long service life when used in harsh environments; Good fatigue resistance, able to maintain its stability and reliability over long periods of use; Good wear resistance, temperature resistance, and environmental friendliness.

2.2 External dimensions containerized plant factory exterior dimensions;

The external dimensions of the containerized plant factory are 12.19M * 2.43M * 2.89M. This size is the size of a 40 foot high container according to international standards. It can be easily transported by vehicles and ships in countries such as China, Japan, the United States, France, etc., improving logistics efficiency, and can be quickly deployed to different locations to meet market demand; And it is easy to load, unload, and store, reducing damage during transportation, with high flexibility and mobility; It reduces logistics costs and reduces manual operations, improves safety, and can withstand certain weight and pressure to avoid damage& Nbsp;

2.3 External paint containerized plant factory appearance spray paint type;

The outer paint of the box is made of thick paste modified chlorinated rubber paint, which has excellent anti-corrosion performance, chemical corrosion resistance and weather resistance, and can effectively resist corrosion under harsh conditions such as salt spray, industrial atmosphere, and marine environment; Having good adhesion and durability, it can also maintain gloss for a long time, thereby extending the service life of containers; Has excellent decorative properties, enhances the appearance quality of the container, making it more beautiful and generous; Good environmental performance, reducing environmental pollution, meeting the requirements of painting while also meeting the requirements of sustainable development; Easy to maintain, resistant to sunlight aging& Nbsp;

2.4 Insulation Structure;

The thermal insulation material is polyurethane sprayed foam, and the thickness of the thermal insulation layer is 100mm. It has good airtightness, effectively controls moisture and heat, ensures the uniformity of temperature and humidity inside the chamber, plays a role in insulation and moisturizing, can effectively reduce heat transfer, maintain stable temperature inside the plant factory, and provide a suitable growth environment for plants; In addition to thermal insulation, polyurethane spray foam also has excellent thermal insulation performance, which can effectively block the impact of external temperature fluctuations on the plant factory interior, reduce energy waste, and maintain the comfort of the internal environment; Strong durability, not prone to aging, corrosion, and deformation; It has good environmental performance, does not contain harmful substances, does not cause pollution to the environment, reduces energy consumption, and extends the service life of the equipment inside the box& Nbsp;

2.5 Internal Structure Container Plant Factory Internal Structure;

The containerized plant factory has a preparation area, planting area, and optional equipment area inside, equipped with different numbers of planting racks according to different configurations for users to choose from:;

Equipped with a washbasin: capable of accommodating 2 rows of 16 planting racks& Nbsp;

No washbasin configuration: can accommodate 2 rows of 18 planting racks& Nbsp;

Equipment area: equipped with a washbasin that can accommodate 2 rows of 14 planting racks; No washbasin configuration: can accommodate 2 rows of 16 planting racks;

Part 3: Air system internal circulation system;

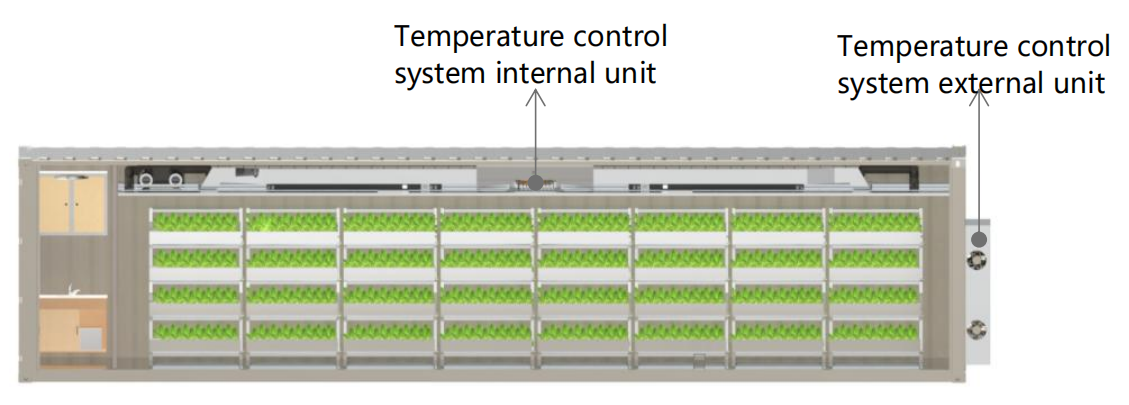

3.1 Air conditioning temperature control system;

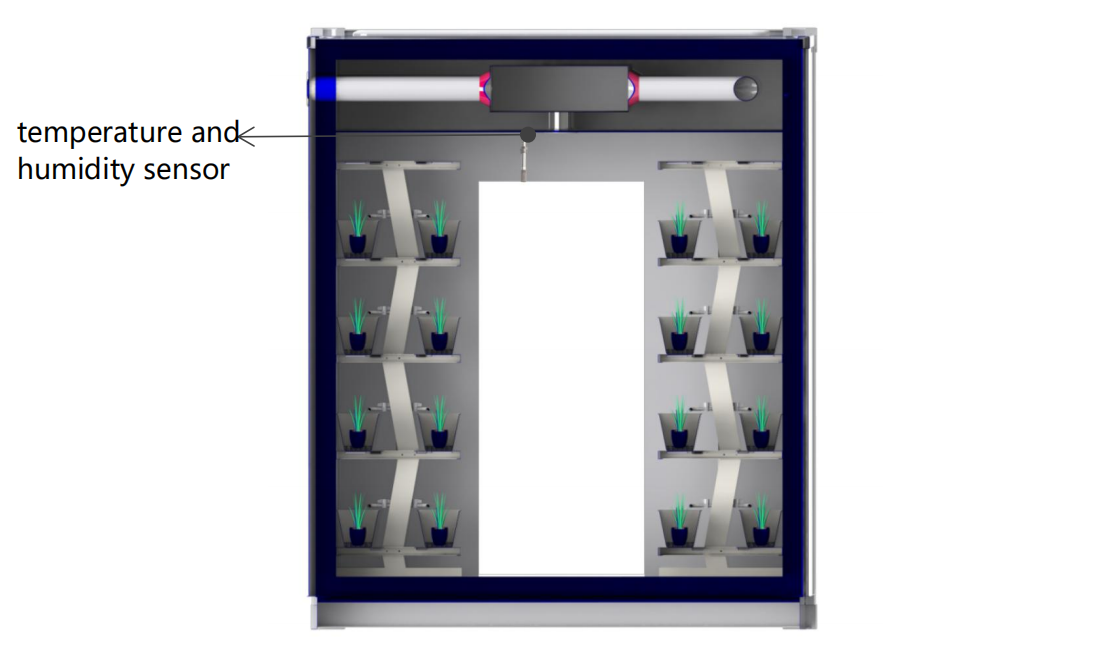

The temperature control system can monitor the temperature changes in the planting area in real time. By analyzing, processing, and providing feedback on the data collected by the temperature sensor, the indoor temperature can be automatically adjusted to maintain the environmental temperature within the optimal growth range. Meanwhile, more precise temperature control and energy conservation can be achieved through intelligent control& Nbsp;

Equipment: Temperature control system internal unit, temperature control system external unit, temperature sensor

Figure 3.1 Schematic diagram of the internal and external units of the temperature control system

Figure 3.2 Schematic diagram of temperature and humidity sensor

3.2 Carbon dioxide density control Carbon dioxide control system

The carbon dioxide control system can monitor the changes in carbon dioxide concentration in the planting area in real time. By analyzing and processing the monitored data and providing feedback, it can automatically adjust the indoor carbon dioxide concentration, improve the efficiency of plant photosynthesis, and ensure the foundation of energy and nutrients required for plant growth. Meanwhile, through intelligent control and automated regulation, fast and accurate control of carbon dioxide concentration can be achieved& Nbsp;

Equipment: Carbon dioxide sensor

Figure 3.3 Schematic diagram of carbon dioxide concentration sensor

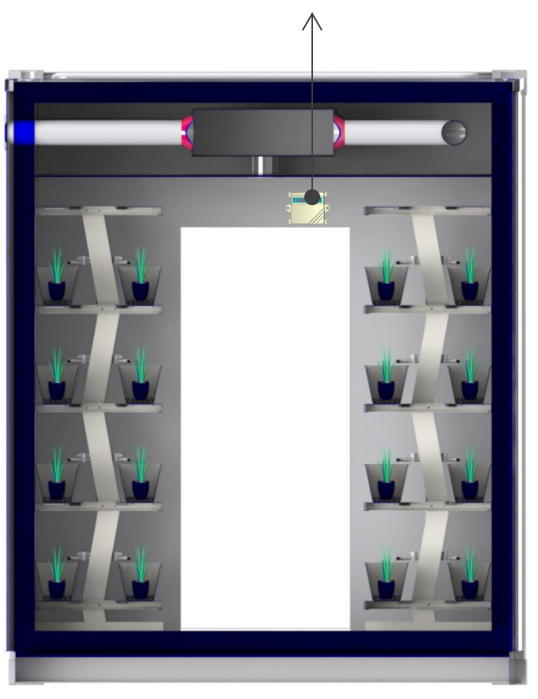

3.3 Air circulation;

The fresh air system reduces the impact of external climate on the internal temperature of the plant factory while introducing fresh air. The system will control the opening or closing of the equipment based on the user's set opening and closing time. When the internal humidity or carbon dioxide concentration is below or above the normal range, the system will also control the opening or closing of the equipment. Maintain appropriate humidity and carbon dioxide concentration to ensure healthy growth of plants& Nbsp;

Maintain a certain flow of internal air to ensure the uniformity of internal temperature, humidity, and carbon dioxide concentration, and to ensure the quality of the air environment and temperature stability inside the plant factory. Maintain internal temperature, humidity uniformity, and wind pressure stability through air ducts. Excessive temperatures may accelerate plant transpiration, while excessively low temperatures may cause cold damage to plants. Reducing heat transfer helps prevent temperature fluctuations and creates a more stable environment for plant growth.

Schematic diagram of the location of the heat exchanger

3.4 Air Sanitation UV Sterilization;

The UV sterilization equipment is installed in the microcirculatory duct and uses ultraviolet radiation to sterilize and disinfect the air flowing through, effectively killing 99.9% of bacteria and viruses in the air and promoting healthy plant growth. At the same time, the system will control the opening and closing of the device based on the user's set opening or closing time& Nbsp;

3.5 Air system optional installation products [*]

3.5.1 De humidifier dehumidifier;

Adjusting humidity: Dehumidifiers can reduce the humidity inside the container, thereby maintaining a humidity environment suitable for plant growth. For many plants, excessive humidity can lead to the breeding and spread of pests and diseases, so dehumidifiers play an important role in maintaining healthy plant growth& Nbsp;

Prevent mold growth: Excessive humidity can easily lead to the growth of mold and bacteria, which is not only detrimental to plant growth but may also pose a threat to human health. Dehumidifiers can effectively prevent the growth of mold and bacteria by reducing humidity.

Protective equipment: Excessive humidity may cause damage to electronic devices and sensors inside container plant factories. Dehumidifiers can protect these devices from the invasion of humid environments and extend their service life by maintaining appropriate humidity& Nbsp;

Improving energy efficiency: Dehumidifiers can remove moisture from the air, making it drier, which helps improve the thermal efficiency inside the container. This is of positive significance for maintaining temperature stability inside plant factories and improving energy efficiency. When the humidity sensor detects that the humidity is greater than the set value, the system will control the dehumidifier to turn on. When the humidity drops to the set value, the system will control it to turn off& Nbsp;

3.5.2 CO2 gas tank;

Increase indoor carbon dioxide concentration to provide a stable and pure source of carbon dioxide for plant factories. In plant factories, carbon dioxide cylinders are connected to specific equipment and systems to accurately control the amount and rate of carbon dioxide release to meet the needs of plant growth. When the carbon dioxide concentration sensor detects that the indoor concentration is below the set value, the system will control the solenoid valve to release carbon dioxide gas from the carbon dioxide cylinder into the room. When the sensor detects that the indoor carbon dioxide concentration has increased to the set value, the system will control the solenoid valve to close and stop the release of carbon dioxide gas& Nbsp;

By supplementing carbon dioxide into plant factories, the efficiency of plant photosynthesis can be improved, promoting plant growth and development. This is of great significance for increasing the yield of plant factories, improving plant quality, and achieving efficient and sustainable agricultural production.